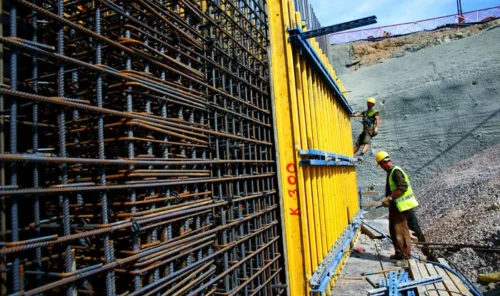

Rebar Detailing is the key to personnel on the construction site. They are detailed construction processes, mainly working for fabricators, contractors, or structural engineering consultants.

Rebar detailers typically work closely with architects, engineers, and other construction professionals to ensure that the rebar design meets the necessary structural and safety requirements. Also, be responsible for coordinating with rebar fabricators and contractors to ensure that the rebar is delivered and installed according to the drawings and specifications.

Are you thinking to hire the rebar detailers? Because when our customers think about the rebar detailing service for any requirement, the MechCiv Designer’s first name comes to mind. We provide the best rebar drawing & designing shop service and the 3D rebar service. Any concerns about the project’s constructability are addressed immediately before the first rebar is twisted or sheered.

Need any help or want to hire the experts of Rebar detailers

But, do you know what Rebar Detailing Service is, and what is the purpose of hiring Rebar detailers? Let’s know its importance and what it is.

What is Rebar Detailing?

Rebar detailing is the process of producing detailed drawings and specifications for the placement and installation of reinforcing steel (rebar) in a concrete structure. It involves creating detailed drawings that include information such as the size and type of rebar to be used, the spacing and location of the rebar within the concrete structure, and the connection details for the rebar.

Rebar detailers use specialized software and tools to create the drawings and specifications, which are used by contractors and fabricators to ensure that the rebar is placed and connected correctly. It is an important part of the construction process, as it helps to ensure the strength and stability of the finished structure.

Rebar Detailing involves creating detailed drawings and specifications that include information such as:

- The size and type of rebar to be used

- The spacing and location of the rebar within the concrete structure

- The connection details for the rebar, including details on how the rebar will be anchored and tied together

- Are any special requirements or considerations for the rebar, such as corrosion protection or fire resistance

Rebar detailing is typically done by specialized rebar detailers who have knowledge and experience in working with reinforcing steel. It is an important part of the construction process, as it helps to ensure the safety and integrity of the finished structure.

Why it is Important to Hire the Right Person for Rebar Detailing

It is important to hire the right person for rebar detailing because this process plays a critical role in the overall construction process. Rebar detailing involves creating detailed drawings and specifications for the placement and installation of reinforcing steel in a concrete structure, and these drawings and specifications must be accurate and complete.

An experienced and knowledgeable rebar detailer will have the necessary skills and expertise to create accurate and detailed drawings and specifications that meet the required standards for quality and safety. They will also be able to identify any potential issues or challenges that may arise during the construction process, and work with the team to find solutions.

In addition to their technical skills, a good rebar detailer should also be able to work well with others and be able to communicate effectively with team members and stakeholders. They should be able to manage their time effectively and meet deadlines in a fast-paced and dynamic construction environment.

Overall, hiring the right person for rebar detailing is important because it can help to ensure the success and safety of the construction project.

Most Frequent Problems with 2D Rebar Details

There has been a shift in recent years from traditional two-dimensional (2D) drawings to three-dimensional (3D) drawings in many industries, including architecture, engineering, and construction. This shift has been driven by advances in technology and software that have made it easier to create and work with 3D drawings.

Some of the most common pain points of 2D rebar detailing include:

- Difficulty visualizing the design: It can be challenging to visualize the final result when working with 2D drawings, especially for more complex or detailed designs. This can make it harder to identify potential issues or conflicts and can lead to errors or rework during the construction process.

- Lack of accuracy: 2D drawings can be less accurate than 3D drawings, as they do not show all dimensions and angles in three dimensions. This can lead to misunderstandings or errors in the placement and connection of the rebar.

- Poor communication: 2D drawings can be more difficult to share and review with team members and stakeholders, which can hinder communication and collaboration.

How to Solve Them with 3D Design Tools

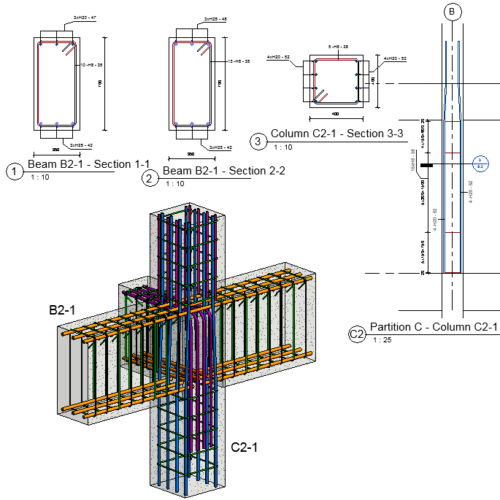

3D design tools can help overcome these challenges by providing a more immersive and accurate design representation. Some specific ways that 3D design tools can help include:

- Improved visualization: 3D design tools allow you to view the design from any angle and see how the rebar fits within the overall structure. This can help to identify potential issues or conflicts and make it easier to visualize the final result.

- Increased accuracy: 3D design tools can show all dimensions and angles in three dimensions, which can help to reduce errors and improve the accuracy of the rebar detailing.

- Enhanced communication: 3D design tools can make it easier to share and review the design with team members and stakeholders, which can improve communication and collaboration.

Overall, 3D design tools can help to improve the efficiency and accuracy of rebar detailing and can help to overcome some of the common pain points associated with 2D rebar detailing.

Software Used for Rebar Detailing; What are they?

The traditional tools used by detailers were pencil and paper, T-squares, triangles, templates, and drawing machines. These have all been substituted by modern computer tools and accepted business software.

Detailers make drawings using a software technology called CAD(computer-aided drafting). The most well-known software program created by Autodesk for this purpose is called Autodesk Rebar, and it also happens to be the most well-known brand in the industry. RebarCAD and Tekla Structures are other programs with a similar focus used for Rebar detailing.

For any Rebar Detailing Services Contact Us. Globally, we are one of the top agency MechCiv designers.