Why Choose Precast Stairs?

Precast stairs offer numerous advantages that make them a preferred choice in the construction industry. Their precast nature ensures consistent quality and faster installation, leading to significant time and cost savings. They are durable, weather-resistant, and can withstand heavy loads, providing long-lasting support for your structures. Whether it’s for residential, commercial, or industrial projects, precast stairs are an excellent addition that enhances safety and functionality.

Why is Precast stairs important?

In the United States, precast stairs have emerged as the preferred choice for various construction projects, and for good reasons. With their exceptional durability, rapid installation, and cost-effectiveness, precast stairs have become a sought-after solution across a wide range of industries. From commercial buildings and educational institutions to industrial facilities and residential complexes, precast stairs offer numerous benefits that elevate the overall construction process.

What sets MechCiv Designers apart?

At MechCiv Designers, we take pride in providing top-notch precast stairs services that cater to the specific needs and requirements of our clients in the USA. With our expertise in BIM Modeling Services and precise attention to detail, we deliver precast stairs solutions that enhance the aesthetic appeal and functionality of any building. Whether it’s a modern architectural design or a traditional structure, our precast stairs blend seamlessly with the overall vision, adding value and elegance to the project.

Our Precast Stairs Services

At MechCiv Designers, we specialize in providing top-notch precast stairs services to meet the diverse needs of our clients in the USA. Our team of skilled professionals has a deep understanding of precast design and construction methodologies, ensuring that your project’s stairs are executed with precision and efficiency. Our range of precast stairs services includes:

Custom Design and Engineering

Our experts work closely with you to understand your project requirements and create custom precast stair designs that perfectly align with your vision.

Quality Manufacturing

We use cutting-edge technology and the finest materials to manufacture precast stairs that meet the highest quality standards and comply with industry regulations.

Timely Installation

Our team ensures that the precast stairs are delivered and installed within the agreed-upon timeframe, minimizing any delays and disruptions to your project schedule.

Safety and Compliance

Safety is paramount in every construction project. Our precast stairs are designed and installed to meet all safety codes and standards, ensuring a secure and reliable structure.

Efficient Project Management

From design to installation, our project management approach ensures seamless coordination and communication, streamlining the entire process.

Sustainability

Precast stairs are known for their sustainability benefits, as they reduce waste, require fewer raw materials, and offer energy-efficient solutions for your projects

Why Choose MechCiv Designers for Precast Stairs Services?

When you partner with MechCiv Designers for your precast stairs requirements, you can expect a host of benefits that set us apart from the competition:

Expertise

Our team of engineers and designers possesses extensive experience in precast design and construction, ensuring that your project is in capable hands.

Precision and Quality

We prioritize precision in every step of the process, from design to manufacturing and installation, to deliver precast stairs of exceptional quality.

Cost-Effectiveness

By leveraging our expertise and efficient approach, we offer cost-effective precast stairs solutions that fit your budget without compromising on quality.

Customer-Centric Approach

We believe in building strong relationships with our clients, and our customer-centric approach ensures that we address your unique requirements with dedication and care.

Timely Delivery and Quality

We understand the importance of project timelines, and our commitment to on-time delivery ensures that your precast stairs are ready when you need them.

Industry Compliance

Our precast stairs services adhere to all relevant industry standards and regulations, giving you peace of mind and confidence in the final outcome.

Benefits of Precast Stairs in USA

Precast stairs offer a multitude of benefits that make them an excellent choice for construction projects:

Durability

Precast stairs are known for their exceptional durability, as they are manufactured using high-quality concrete and reinforcement materials. This ensures that the stairs can withstand heavy loads and harsh environmental conditions, making them suitable for long-term use.

Time Savings

One of the key advantages of precast stairs is the significant time savings they offer during construction. As precast stairs are manufactured off-site in a controlled environment, they can be quickly installed on-site, reducing construction time and expediting project completion.

Cost-Effectiveness

By opting for precast stairs, construction projects can save on labor and material costs. The streamlined manufacturing process and reduced on-site work lead to cost efficiencies, making precast stairs a cost-effective solution.

Safety

Precast stairs are designed and manufactured with strict adherence to safety standards. The precision and consistency in their production ensure uniformity and stability, minimizing the risk of accidents and providing a safer environment for occupants.

Sustainability

Incorporating precast stairs into a building project aligns with sustainable construction practices. The use of eco-friendly materials, reduced waste generation, and energy-efficient production methods contribute to a greener and more sustainable construction approach.

Types of Precast Stairs available in USA

There is a diverse range of precast stairs available specific for USA, each catering to specific design preferences and functional requirements:

Straight Stairs

Simple and functional, straight precast stairs are the most common type used in various construction projects. They offer ease of installation and suit buildings with limited space.

Curved Stairs

Ideal for adding an elegant touch to architectural designs, curved precast stairs are custom-designed to follow curved or helical configurations, enhancing the aesthetic appeal of the structure.

Helical Stairs

Helical precast stairs are gracefully curved and spiral around a central column. They are a striking architectural feature and are often found in upscale buildings, hotels, and luxury residences.

Spiral Stairs

Compact and visually appealing, spiral precast stairs are a space-saving solution suitable for buildings with restricted floor space. They add a touch of elegance to both interior and exterior designs.

Frequently Asked Questions (FAQs) :

Are precast stairs as durable as traditional cast-in-place stairs?

Precast stairs are known for their durability and strength, comparable to traditional cast-in-place stairs. The use of high-quality materials and controlled manufacturing processes ensures their long-lasting performance.

Can precast stairs be customized to suit specific design preferences?

Yes, precast stairs offer a high level of customization. They can be tailored to fit various designs, including straight, curved, helical, and spiral configurations, allowing for flexibility in architectural expression

How do precast stairs contribute to sustainability in construction?

Precast stairs are manufactured in a controlled environment, reducing material waste and resource consumption. Additionally, their durability and low maintenance requirements contribute to a more sustainable building solution.

What is the typical lead time for the delivery and installation of precast stairs?

The lead time for precast stairs can vary depending on the complexity of the design and the manufacturing process. On average, it takes approximately 4 to 6 weeks from design approval to installation.

Are precast stairs suitable for both indoor and outdoor use?

Yes, precast stairs are versatile and can be used for both indoor and outdoor applications. They are designed and manufactured to withstand varying weather conditions and provide safe and reliable access to different areas of a building.

What maintenance is required for precast stairs?

Precast stairs are known for their low maintenance requirements. Regular cleaning and inspections for signs of wear are usually sufficient to keep them in excellent condition. Their durable construction ensures minimal upkeep.

Can precast stairs be integrated into existing buildings during renovations?

Absolutely! Precast stairs can be retrofitted into existing buildings during renovations or expansions. Their customizable nature allows them to seamlessly fit into various architectural styles and space constraints.

How do precast stairs contribute to project cost savings?

The efficiency and speed of precast stairs installation translate into significant project cost savings. Shorter construction timelines, reduced labor costs, and minimized on-site disruptions all contribute to overall budget optimization.

Are precast stairs compliant with building codes and safety regulations?

Yes, MechCiv Designers ensures that all precast stairs are designed and manufactured to comply with relevant building codes and safety regulations. This ensures that the stairs meet the required standards for safety and structural integrity.

Can MechCiv Designers accommodate large-scale projects with precast stairs requirements?

Absolutely! MechCiv Designers has a proven track record of successfully handling large-scale projects that require precast stairs. Our expertise and resources enable us to deliver high-quality precast stairs for projects of any scale.

With MechCiv Designers’ comprehensive BIM Modeling Services and expertise in precast stairs, your construction project is assured of a seamless, efficient, and cost-effective solution. From conceptualization to installation, our team is committed to delivering top-notch precast stairs that elevate the design and functionality of your building. Get in touch with us today to discuss your project requirements and experience the excellence of our precast stairs services. Together, let’s build a structure that stands out for its quality and durability.

Precast Stairs Design Process

Conceptualization

During the initial stage, the design team collaborates with the client to understand their vision and requirements. Concepts and design ideas are brainstormed to create a blueprint for the precast stairs.

Detailed Planning

After finalizing the concept, detailed planning takes place, where the dimensions, specifications, and materials for the precast stairs are determined, considering factors such as load capacity and aesthetic elements.

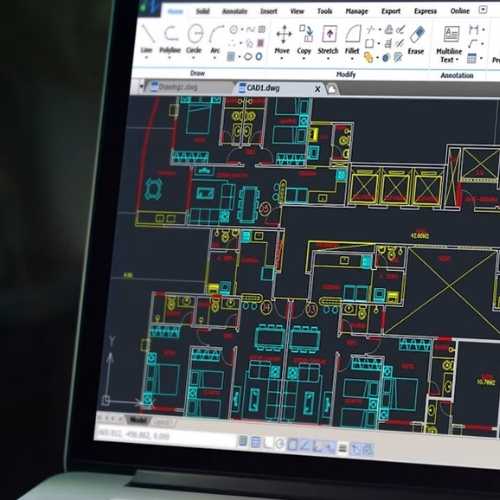

Modeling and Simulation

The design is then translated into a 3D model using advanced BIM software. Simulation tools are employed to test the structural integrity and performance of the precast stairs under different conditions.

Detailing and Documentation

Precise detailing is carried out to produce technical drawings and documentation, including fabrication drawings and assembly instructions, which are crucial for the manufacturing process.

Manufacturing and Quality Control

The approved design is sent to the precast manufacturing facility, where skilled craftsmen use molds to produce the precast stairs. Stringent quality control measures ensure the stairs meet industry standards.

On-Site Installation

Once manufactured, the precast stairs are delivered to the construction site, where they are expertly installed by experienced technicians, ensuring seamless integration with the building’s structure.

Testimonial

In order to create the project, MechCiv Designers overcame many obstacles, and the client is pleased with the engagement thus far. They continuously give updates on the project’s status.

I appreciate MechCiv Designers’ aesthetic taste and communication skills. Future clients will come across a well-organized partner with distinctive, premium style.

We are quite happy with the dashboard, particularly with its user-friendly interface. MechCiv Designer’s dedication to producing excellent results made it a true partnership. They work well together as a team.

The team is putting a lot of effort into completing the project properly and advancing the goals and objectives of their clients. Best CAD Outsourcing company i have worked till date.

Looking to elevate your construction projects with precise precast detailing services in Australia?

Get in touch with us today to discuss your precast detailing requirements and receive a free quote. Our team is dedicated to delivering accurate and efficient precast shop drawings to help you achieve construction excellence.

Contact MechCiv Designers now for expert assistance and a seamless precast detailing experience.