Introduction: The Cost of Fabrication Errors in Steel Construction

In structural steel projects, precision is everything.

Even a small mismatch in bolt alignment, connection detail, or member length can result in costly delays, fabrication rework, and wasted material.

Studies show that fabrication errors can account for up to 7–10% of total project costs, primarily due to design discrepancies and miscommunication between disciplines.

Traditional 2D detailing, while still widely used, often fails to deliver the visual and spatial accuracy required for today’s complex steel structures. That’s where Building Information Modeling (BIM) makes a fundamental difference — transforming how detailing is done.

At MechCiv Designers LLP, we have implemented BIM workflows to bring unmatched precision, coordination, and constructability into our steel detailing process.

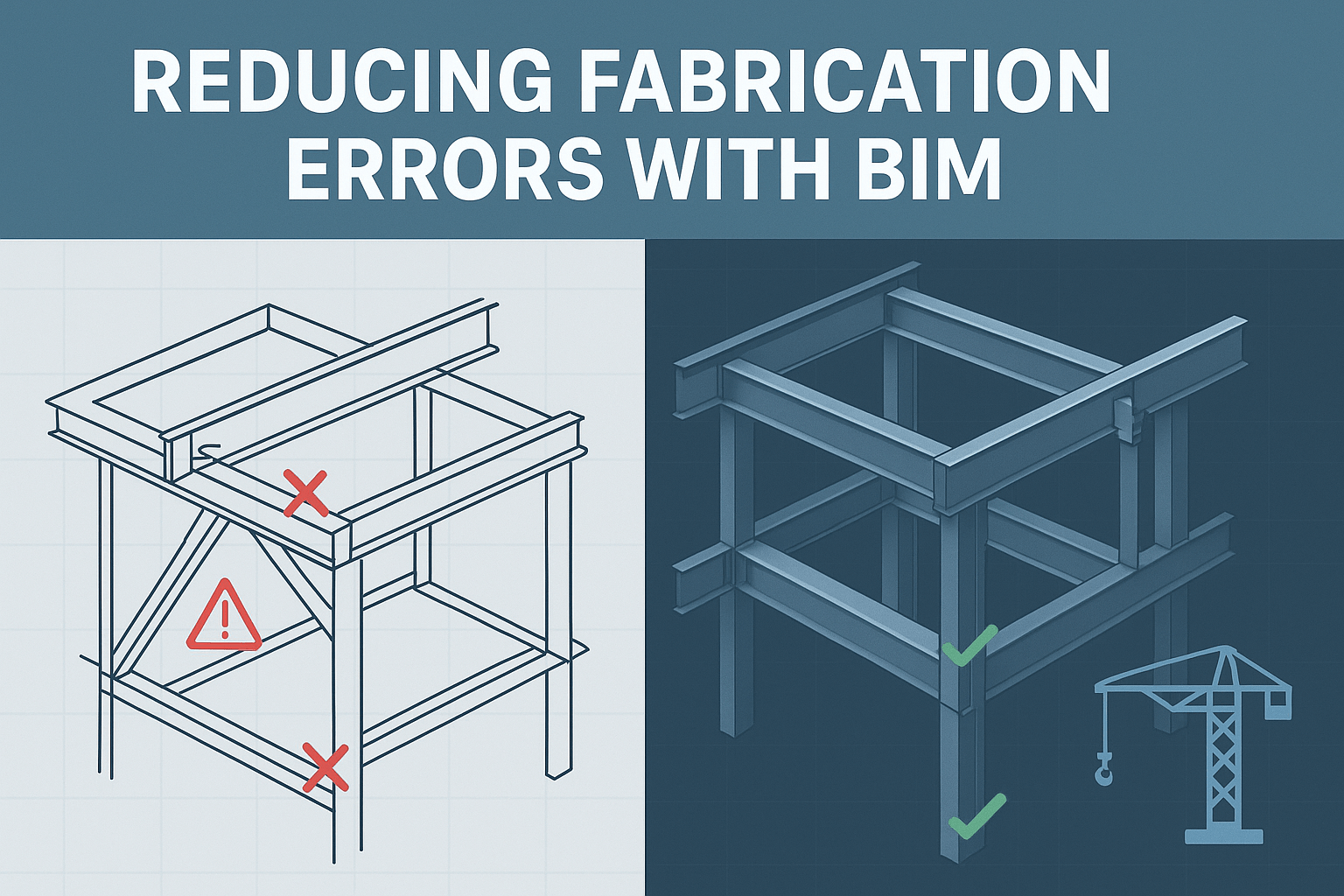

The Challenge with Traditional 2D Steel Detailing

Before BIM, steel detailing was heavily dependent on manual coordination and drawing interpretation.

This method often resulted in:

- Misaligned connections: due to limited visibility between components.

- Clash conflicts: between steel, architectural, and MEP elements.

- Inconsistent updates: where design changes weren’t reflected across all drawings.

- Manual take-offs: leading to errors in quantity estimation.

These challenges make it difficult to maintain synchronization between design, fabrication, and site teams — leading to inefficiencies and rework that slow down project delivery.

How BIM Steel Detailing Transforms the Workflow

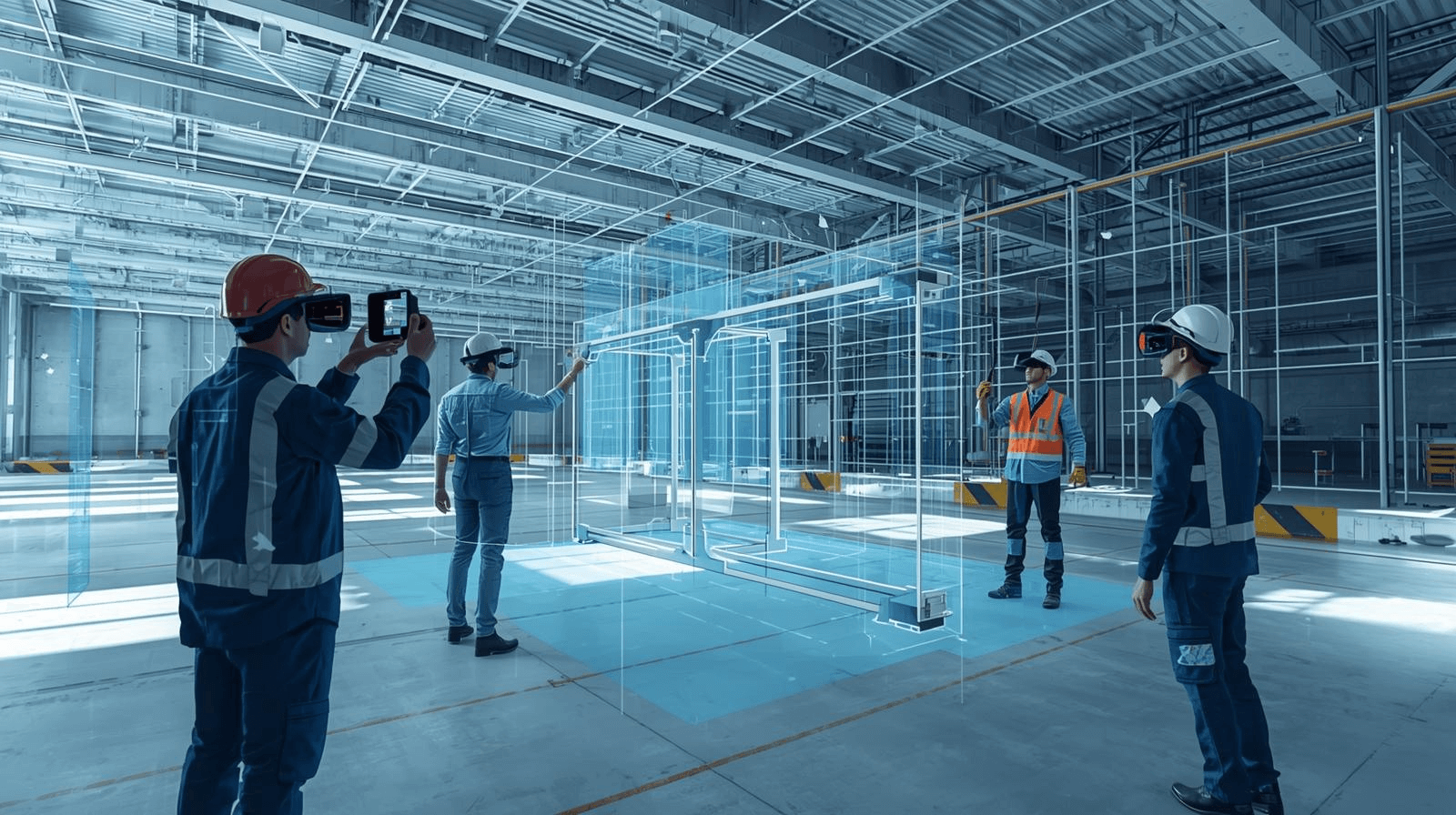

BIM detailing uses intelligent 3D models to represent every steel member, plate, and connection digitally — allowing all stakeholders to collaborate using a single, data-rich model.

Here’s how it transforms the entire steel fabrication workflow:

1️⃣ Precision Through 3D Visualization

Each element of the structure — from beams and bracings to gusset plates and bolts — is modeled in 3D, providing a complete visual understanding before fabrication begins.

This helps designers, fabricators, and contractors detect potential constructability issues early.

2️⃣ Clash Detection and Coordination

Using BIM coordination tools, all structural, architectural, and service models are combined to identify clashes automatically.

Conflicts like overlapping ducts, columns, or embedded plates are resolved before fabrication starts — reducing costly on-site adjustments.

3️⃣ Automated Shop Drawings and Reports

Once the model is finalized, shop drawings, GA drawings, and part lists are auto-generated directly from the BIM environment.

This ensures absolute consistency — every detail in the drawing matches the 3D model exactly.

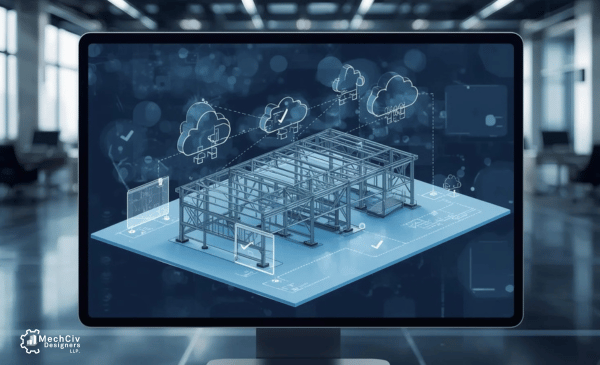

4️⃣ Centralized Collaboration and Version Control

With cloud-based collaboration (like Trimble Connect, BIM 360, or similar platforms), teams can work simultaneously across locations.

Every stakeholder — from design consultants to fabricators — always works with the latest version, eliminating confusion from outdated drawings.

Real-World Application: Industrial Steel Structure Case

In a recent large-scale industrial project, our detailing team was responsible for delivering a complete structural steel detailing package using BIM.

Scope of Work:

- Complete 3D modeling and detailing of primary & secondary steel members

- Connection design as per AISC standards

- Generation of fabrication and erection drawings

- Coordination with architectural and MEP teams

Our Approach:

- Used Tekla Structures for 3D modeling and automated drawing generation

- Integrated BIM coordination with design consultants to ensure constructability

- Conducted multiple virtual review sessions before fabrication release

Results Achieved:

✅ Zero fabrication rework due to early clash detection

✅ 30% reduction in drawing approval time through coordinated 3D model reviews

✅ Accurate CNC data generated directly from the BIM model

✅ Seamless communication between design, fabrication, and erection teams

This project demonstrated how BIM can bring design accuracy, fabrication efficiency, and on-site reliability into a single workflow.

Quantifiable Benefits of BIM Steel Detailing

| Benefit | Traditional Method | BIM-Based Method |

| Error Detection | Manual and reactive | Automated and proactive |

| Drawing Updates | Repetitive and prone to oversight | Linked and synchronized automatically |

| Coordination | Fragmented communication | Real-time multi-discipline collaboration |

| Fabrication Accuracy | Based on 2D interpretation | Based on 3D constructible data |

| Delivery Time | Delayed due to rework | Faster due to automation and accuracy |

By eliminating manual coordination and enhancing visualization, BIM ensures “Right the First Time” fabrication results.

Why BIM-Based Detailing is the Future of Construction

The AEC industry is rapidly adopting BIM because of its ability to integrate design, data, and delivery.

For steel structures, BIM acts as a bridge between engineering and manufacturing, helping teams visualize and optimize every stage before production.

Key Advantages:

- Reduced fabrication waste through precise modeling

- Streamlined approval workflows

- Enhanced documentation traceability

- Real-time updates for revisions and design changes

- Compatibility with digital fabrication and ERP systems

The integration of 4D (time) and 5D (cost) BIM now enables engineers and fabricators to plan not just what will be built — but when and how much it will cost.

Why Choose MechCiv Designers LLP

At MechCiv Designers LLP, our goal is to make every steel structure error-free, buildable, and efficient.

Our detailing process is backed by:

- A skilled team of BIM engineers and structural detailers

- Experience across industrial, commercial, and infrastructure projects

- Adherence to AISC, AS, BS, and IS standards

- Advanced BIM tools like Tekla Structures, Revit, and Navisworks

- Robust QA/QC processes to ensure accuracy before delivery

We go beyond producing drawings — we deliver digital precision models that drive real-world construction success.

Key Takeaways

- BIM-driven detailing eliminates manual errors through 3D modeling and coordination.

- Clash detection and real-time collaboration reduce rework and delays.

- Automation enhances drawing accuracy, quantity take-offs, and fabrication readiness.

- Better visualization ensures smoother communication between all project teams.

Conclusion: Building Smarter, Faster, and Error-Free

Fabrication accuracy starts with detailing accuracy — and BIM ensures just that.

By integrating design intelligence, data coordination, and model-based automation, BIM steel detailing is helping the industry move toward zero-error fabrication and faster project delivery.

Whether it’s a commercial high-rise, warehouse, or industrial structure, MechCiv Designers LLP delivers the precision and coordination modern construction demands.

💬 Ready to experience error-free detailing?

Contact our BIM experts to discuss your next project today.