The construction and engineering industry is undergoing a digital transformation. With globalization and the rise of remote work, engineering firms are no longer confined to local teams and physical offices. Instead, projects now involve multinational teams collaborating in real-time across borders.

For steel detailing projects, where precision, version control, and timely delivery are critical, this shift introduces both opportunities and challenges. The question becomes: How can remote teams maintain accuracy, efficiency, and quality while working from different locations?

The answer lies in the powerful combination of cloud-based collaboration platforms, adherence to BIM (Building Information Modeling) standards, and robust quality control processes.

In this blog, we’ll explore how these three pillars work together to redefine the future of remote steel detailing.

🔑 1. The Rise of Cloud-Based Collaboration in Steel Detailing

Traditional methods of steel detailing often relied on local servers, emails, and manual file-sharing. These approaches were time-consuming, error-prone, and limited scalability. As projects grew larger and teams became more dispersed, it became clear that a better system was needed.

📌 What is Cloud-Based Collaboration?

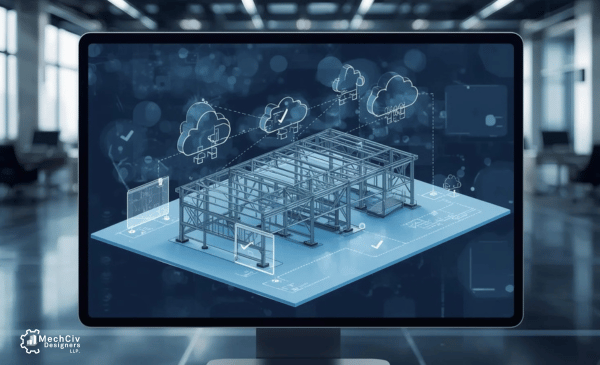

Cloud-based collaboration allows teams to work on the same project data in real-time from anywhere in the world. With centralized access to models, drawings, and documents, cloud platforms eliminate bottlenecks and ensure that all stakeholders are working on the latest version of the project.

🚀 Benefits for Steel Detailing:

- Real-Time Access – Engineers, modelers, and fabricators can update and view changes instantly.

- Version Control – Every revision is tracked, eliminating confusion caused by outdated files.

- Reduced Delays – Faster decision-making with approvals, RFIs, and comments handled online.

- Scalability – Easily onboard new team members and contractors without IT hassles.

- Cost Efficiency – Save on physical infrastructure and IT maintenance.

🌍 Popular Cloud Platforms:

- Autodesk BIM 360 – Widely used for multidisciplinary collaboration.

- Tekla Model Sharing / Trimble Connect – Perfect for structural and steel detailing.

- Revit Cloud Worksharing – Enables architects and detailers to coordinate in real-time.

- Navisworks + Cloud – Powerful for clash detection and coordination.

💡 Example: A U.S.-based engineering firm outsourced detailing to an Indian partner via Tekla Model Sharing. By collaborating in real time on the same cloud model, they cut project delivery time by 30% compared to email-based workflows.

📐 2. The Role of BIM Standards in Remote Steel Detailing

When working remotely, one of the biggest risks is misalignment in workflows, file structures, and model accuracy. This is where BIM standards act as the backbone of collaboration.

📌 Why BIM Standards Matter

- Consistency – Ensures uniform drawing formats, naming conventions, and data accuracy.

- Interoperability – Allows models to be exchanged seamlessly across platforms via IFC.

- Quality Assurance – Reduces clashes, errors, and rework through structured data.

- Compliance – Aligns with global codes like AISC (USA), AS/NZS (Australia/New Zealand), and Eurocodes (Europe).

🔧 Key BIM Standards to Follow

- ISO 19650 – The international framework for managing information in BIM.

- LOD (Level of Development) – Defines model detail at each project stage.

- IFC (Industry Foundation Classes) – Facilitates open data exchange.

- National BIM Standards (NBIMS-US, UK BIM Framework, etc.) – Localized guidelines for project delivery.

💡 Example: On a large-scale Australian infrastructure project, following AS/NZS BIM standards enabled seamless collaboration between detailing firms in India, fabricators in Australia, and architects in the UK—despite working remotely.

🛡️ 3. Ensuring Quality Control in Remote Projects

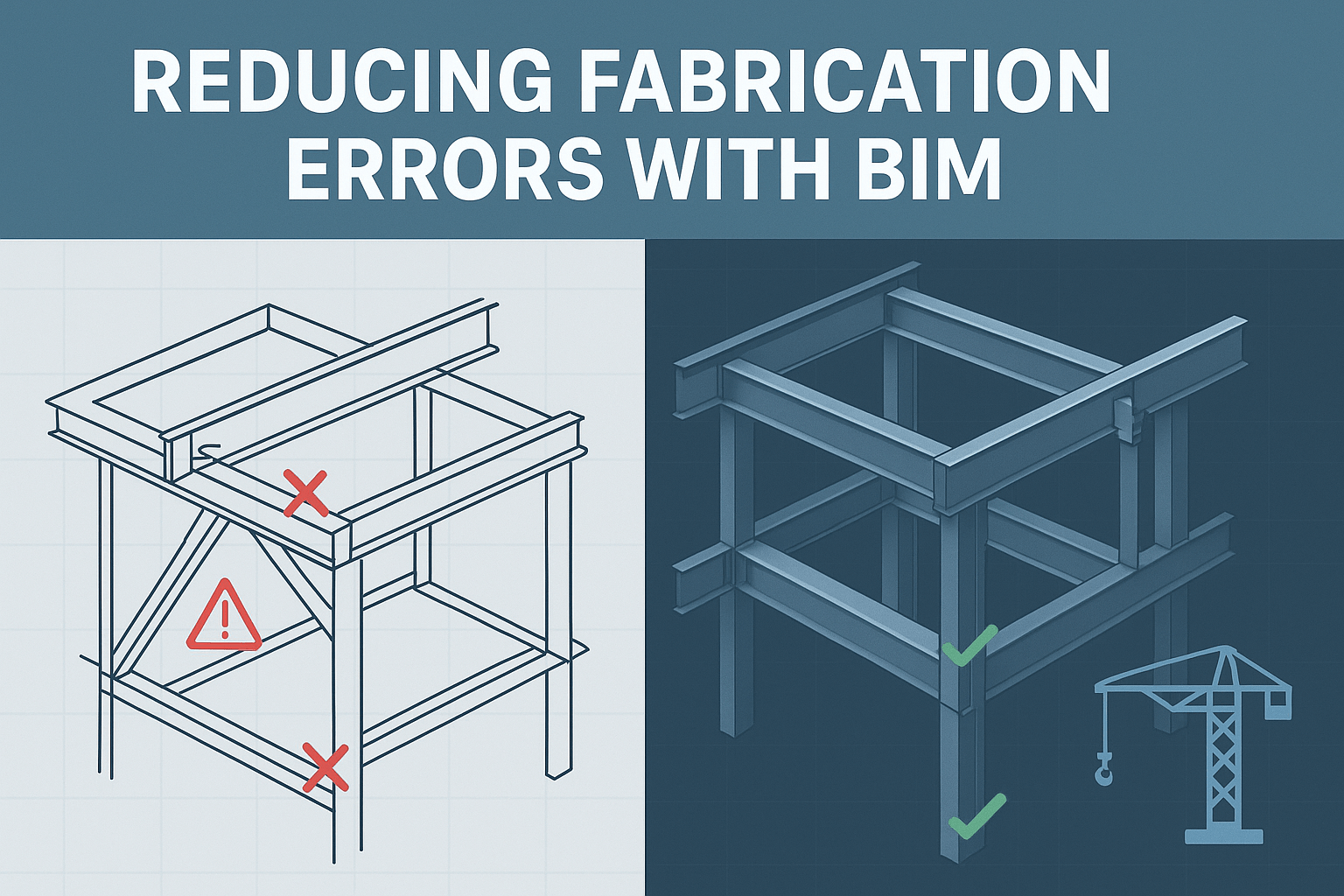

Steel detailing demands millimeter-level accuracy. A single error can cause fabrication issues, delays, and cost overruns. Working remotely adds new challenges, but cloud + BIM workflows actually improve quality when used effectively.

✅ Best Practices for Quality Control

- Automated Clash Detection – Use Navisworks or Tekla to identify conflicts early.

- Peer Review System – Ensure models undergo internal checks before client submission.

- QC Checklists – Standardize checks for bolt holes, welds, connections, and dimensions.

- Audit Trails – Cloud logs every change, ensuring accountability.

- Virtual Coordination Meetings – Regular sync-ups to resolve issues quickly.

📊 Benefits of Digital QC

- Fewer Fabrication Errors – Models arrive shop-ready.

- Faster Approvals – Clients trust the accuracy of submissions.

- Reduced Rework Costs – Minimized onsite modifications.

💡 Example: A detailing project for a U.S. hospital reduced onsite rework by 25% thanks to automated clash detection and cloud-based peer reviews.

📊 4. The Business Impact of Cloud + BIM + QC

Companies implementing this trio report measurable improvements:

- 40% fewer coordination errors due to real-time collaboration.

- 30% faster project delivery through parallel remote working.

- 20–25% cost savings from reduced rework and onsite corrections.

- Improved client satisfaction thanks to transparency and accuracy.

This demonstrates that adopting cloud platforms and BIM standards isn’t just a technical upgrade—it’s a strategic business advantage.

🚀 5. The Future of Remote Steel Detailing

The industry is moving beyond basic cloud tools toward more advanced technologies:

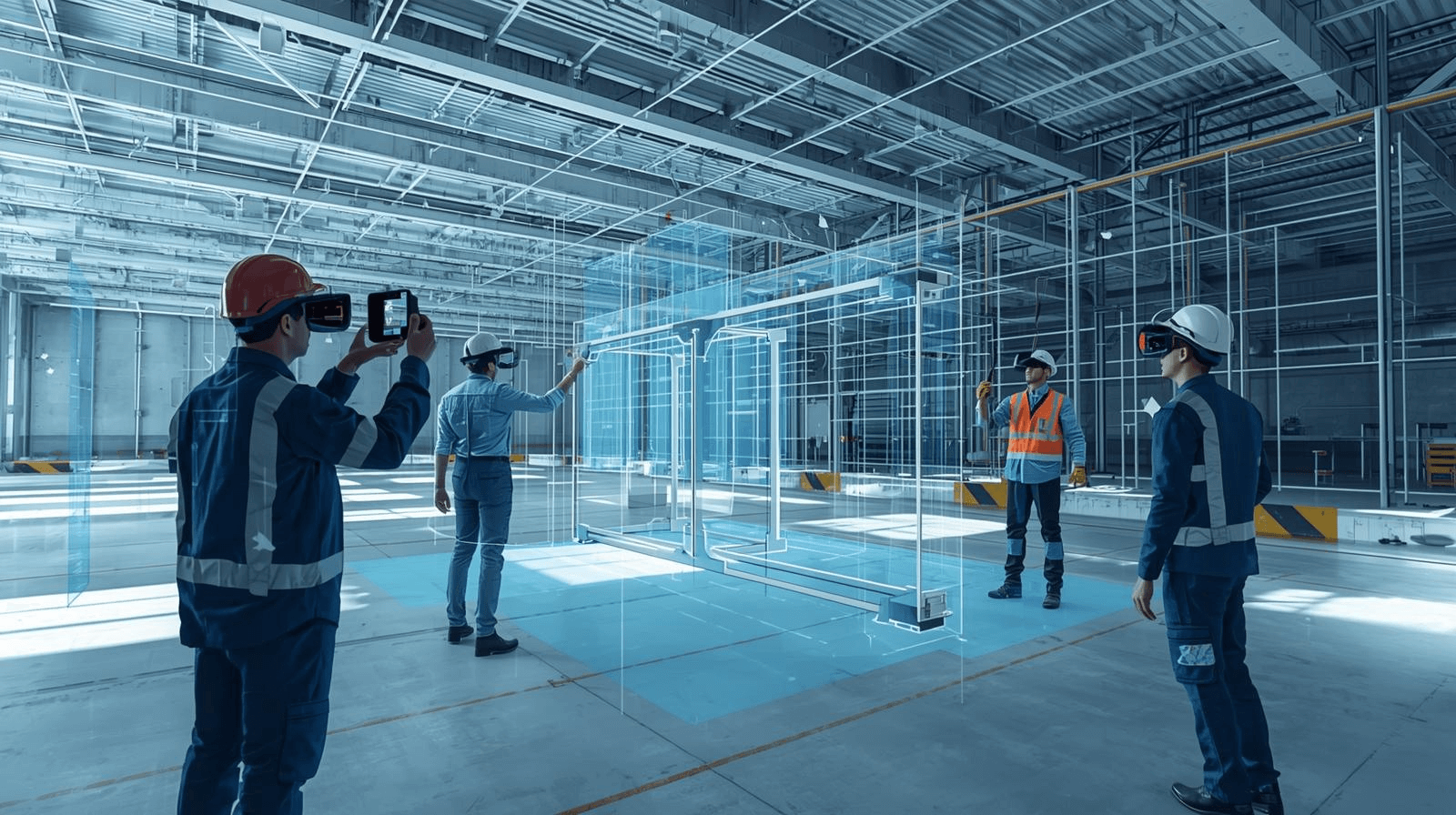

- Digital Twins – Live digital replicas of structures for real-time monitoring.

- AI-Powered QC – Automated clash detection and design optimization.

- IoT Integration – Connecting models with real-world construction sensors.

- Mixed Reality (AR/VR) – Remote site walkthroughs and immersive client presentations.

Companies embracing these innovations will lead the way in global steel detailing and modular construction.

✅ Conclusion

The combination of cloud-based collaboration, BIM standards, and strong quality control has transformed remote steel detailing from a challenge into an opportunity. With the right tools and frameworks, teams can achieve higher accuracy, faster delivery, and greater client satisfaction—all while working across continents.

At MechCiv Designers LLP, we help global clients achieve these results through BIM, CAD, and Steel Detailing services that align with international standards.

📩 Contact us today to discuss how we can support your next project:

🌐 www.mechcivdesigners.com | ✉️ info@mechcivdesigners.com

FAQs

Yes, leading platforms use enterprise-grade encryption and access controls to protect sensitive data.

ISO 19650 is the most widely recognized, providing a universal framework for information management

Absolutely. Cloud platforms are scalable, making them cost-effective even for small-to-medium detailing firms.

It improves it—clients can view models in real-time, reducing approval cycles.

Maintaining consistency across dispersed teams. This is solved through strict BIM standards and centralized cloud workflows.