Introduction

The construction industry is experiencing one of the most significant technological revolutions in decades. From Building Information Modeling (BIM) to Digital Twins, the adoption of advanced tools has streamlined workflows, reduced costs, and enhanced collaboration. Among these cutting-edge technologies, Augmented Reality (AR) and Virtual Reality (VR) are emerging as game changers, particularly in modular construction and steel detailing.

Unlike traditional 2D drawings or even 3D BIM models, AR and VR bring immersive, real-time visualization into the construction process. They bridge the gap between the digital and physical worlds, empowering engineers, contractors, and clients to identify errors early, reduce rework, improve training, and enhance communication. In modular construction projects, where precision and coordination are critical, AR/VR applications can significantly improve efficiency and accuracy.

This article explores the applications, benefits, and future of AR/VR in modular assembly and steel detailing review, highlighting how these technologies are reshaping the construction sector.

What Are AR and VR in Construction?

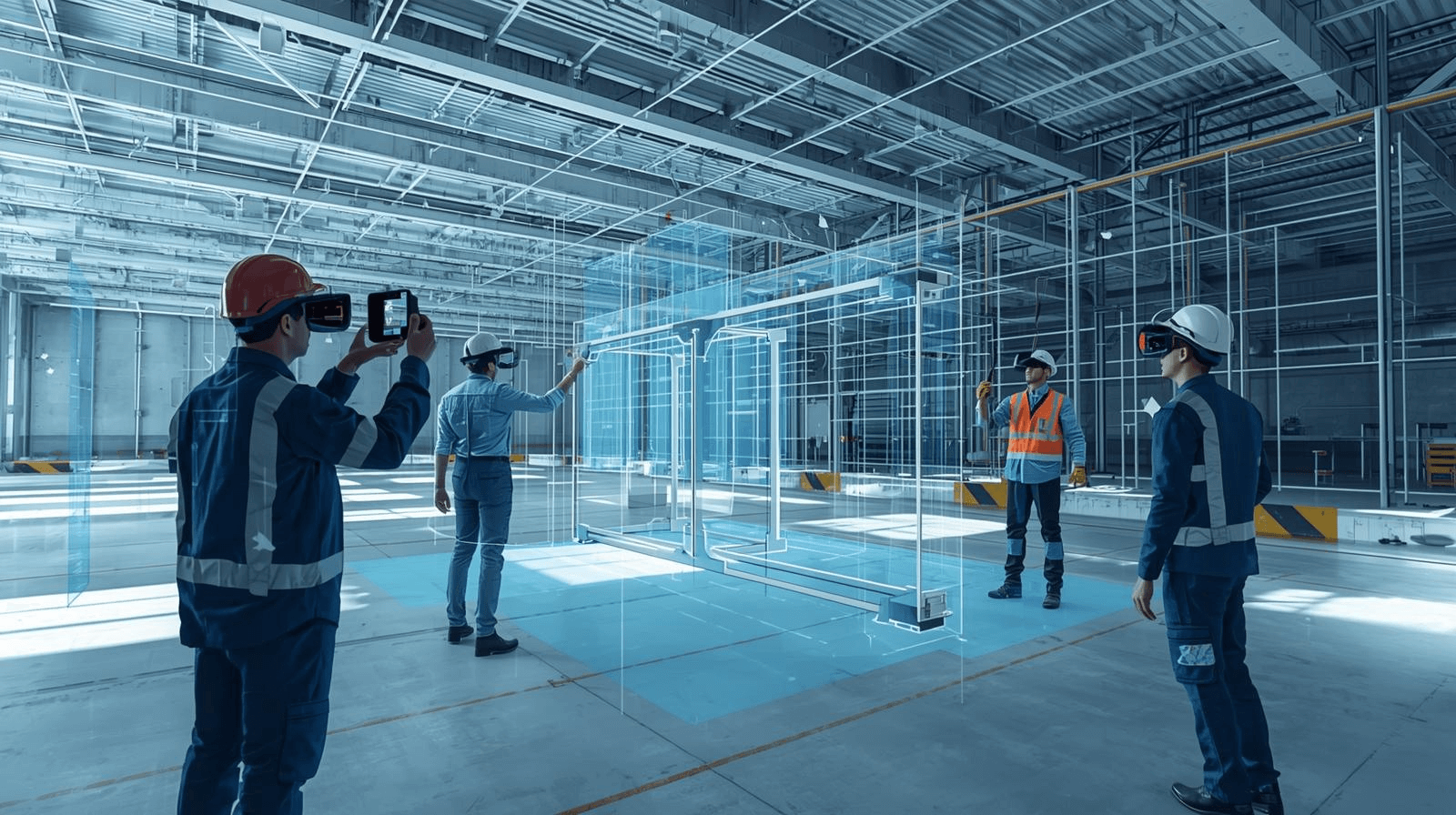

Augmented Reality (AR): Superimposes digital elements (such as BIM models, measurements, or assembly guides) onto the physical construction site through mobile devices, tablets, or AR glasses. This allows workers to “see” the design as they build.

- Virtual Reality (VR): Creates a fully immersive 3D digital environment where stakeholders can walk through a project virtually, review steel detailing models, or simulate modular assembly before construction begins.

Together, AR and VR improve visualization, coordination, and decision-making, particularly in projects involving prefabrication, modular installation, and detailed steel structures.

Why AR/VR Matters in Modular Construction & Steel Detailing

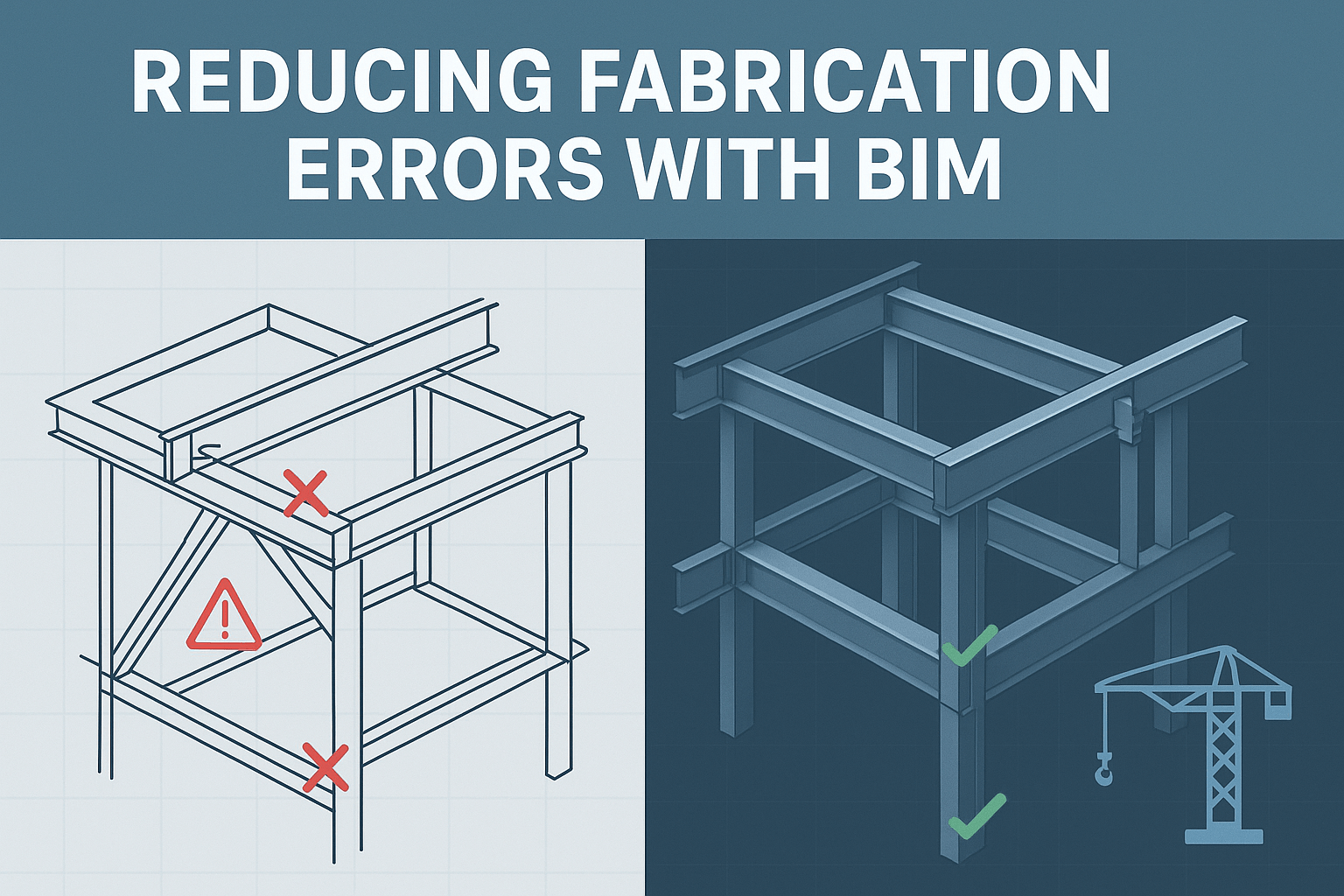

Modular construction and steel detailing require pinpoint accuracy. Modules are manufactured offsite and then assembled on location. Even minor design clashes, misalignments, or measurement errors can lead to costly rework.

Challenges in modular assembly and steel detailing:

- Miscommunication between design and on-site teams.

- Difficulty interpreting complex drawings.

- Errors in alignment during assembly.

- Limited ways to train workers on new tools and processes.

- Client difficulty in visualizing final outcomes.

How AR/VR solves these challenges:

- Provides real-time overlays to ensure components fit correctly.

- Helps crews understand exact placement and orientation.

- Enables immersive training for workers without disrupting live projects.

- Allows clients to virtually experience spaces and approve changes early.

Key Applications of AR/VR in Modular Assembly & Steel Detailing

1. Error Reduction in On-Site Assembly

- AR glasses or mobile devices project digital models over the physical structure, ensuring each steel beam, column, or module is placed accurately.

- Workers can compare the virtual model with the real-world installation in real-time, reducing errors.

2. Steel Detailing Review in Virtual Reality

- Before fabrication, stakeholders can walk through the VR environment and check every joint, connection, and detail.

- Clash detection becomes more intuitive as users identify issues by “being inside” the model rather than just viewing on a screen.

3. Client Walkthroughs & Approvals

- Clients can put on VR headsets to experience the final project before construction begins.

- This not only improves client confidence but also reduces late-stage design changes.

4. Training and Skill Development

- New workers can be trained in modular assembly using VR simulations.

- AR can guide them step-by-step on-site, reducing dependency on supervisors.

5. Remote Collaboration

- Engineers, architects, and project managers across the globe can review AR/VR models together.

- Remote walkthroughs reduce travel costs and speed up approvals.

Benefits of AR/VR in Modular Construction Projects

- Fewer Errors, Less Rework: By detecting clashes early, AR/VR helps avoid costly mistakes.

- Improved Communication: Visual models are easier for all stakeholders to understand than technical drawings.

- Faster Approvals: Clients and regulatory bodies can make decisions quickly after virtual walkthroughs.

- Cost Savings: Reduced rework, travel, and training expenses lead to direct cost benefits.

- Enhanced Safety: Workers can practice dangerous tasks in VR before attempting them onsite.

- Competitive Advantage: Firms adopting AR/VR differentiate themselves as technology leaders in construction.

Case Study Example

Imagine a steel detailing firm working on a large modular hospital project. Using AR glasses, the on-site team overlays the digital steel model onto the partially assembled modules. They immediately detect a misalignment in a beam-to-column connection. Instead of halting assembly, they communicate the issue via cloud-based AR collaboration tools. The detailing team fixes the digital model, and the revised instructions appear instantly on the AR headset. The error is corrected before fabrication, saving weeks of potential rework and thousands of dollars.

Future of AR/VR in Construction

The integration of AR/VR with AI, Digital Twins, and IoT sensors will create real-time intelligent environments where buildings are not only visualized but also continuously monitored throughout their lifecycle. Imagine a future where a modular unit comes with a digital twin that can be viewed in AR, showing maintenance data, sensor updates, and repair guidance.

This convergence of technologies will push the construction industry toward smarter, safer, and more sustainable outcomes.

Conclusion

The use of Augmented Reality and Virtual Reality in modular construction and steel detailing review is no longer experimental—it’s becoming a standard practice. By reducing errors, enhancing training, improving collaboration, and speeding up client approvals, AR/VR empowers construction firms to deliver better projects, faster.

For companies like MechCiv Designers LLP, adopting AR/VR means staying ahead in a competitive market while ensuring precision and quality in every project. The future of modular construction lies not just in building smarter but in visualizing smarter.

Ready to integrate AR/VR into your next project?

Contact MechCiv Designers LLP today to explore how our BIM-powered modular solutions can transform your construction outcomes.